Power Section Stator Elastomer Removal

Reclaim Solutions is the premier stator elastomer removal facility for mud motor power section manufacturers. Our low cost, fast turnaround and quality service enables power section manufacturers to ensure their stator rubber reline operations are not hindered by stator elastomer removal. Let us take the headache out of your stator relines so you can focus on getting your customers' relined power section stators back into production quickly.

Lower Stator Elastomer Reline Costs

In addition to being the lowest rubber removal provider, our mud motor manufacturers benefit from several additional cost savings. We lower your costs by removing your degreasing steps to clean oil, grease and debris from stators and providing the cleanest (rubber & bond free) product. Get better life from your shot media by putting cleaner pipe through the stator injection prep line. Our prices are competitive it makes outsourcing elastomer removal less expensive than in-house processes (including water jet, burnoff ovens and liquid nitrogen).

Reduce Stator Reline Time

Power section stator reline times are critical to your customers, and in a competitive industry where customer orders come without much notice and always with an urgent turnaround, you need a rubber removal solution that can be flexible enough to work with your work order schedule. With such tight stator reline times, making sure your stators come back without bits of rubber requiring reprocessing is essential to your schedule as well as the overall quality of your elastomer reline performance. Our facility is built to do stator rubber removal so you won't be delayed by other orders and parts being processed ahead of your order.

Improve Stator Quality

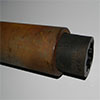

From sample elastomers (for elastomer failure inspection) to pipe ID and OD blasting, we provide our mud motor power section manufacturers with the highest quality rubber removal service. We are the only stator elastomer removal facility that can provide our customers with the elastomer from their stators for inspection. This provides a level of elastomer performance inspection not available to power section manufacturers anywhere else. It is also a clear example of the gentle process used to remove the rubber. You work hard to give your down-hole and thru-tubing customers the best power section available and we work hard to help you do that.

Mud Motor Power Section Stator Elastomer Removal

About Our Stator Elastomer Removal Service

We specialize in power section stator rubber removal. We have built our business around providing mud motor manufacturers with the best in elastomer removal services for their power section stator reline operations. Molding power section stators is tough enough without having to worry about rubber left behind from a burn off oven or water jet cleaning or damage to stators from liquid nitrogen, we provide the cleanest rubber removal service available. From small thru-tubing stators used on directional drilling to large down-hole drilling power section stators, we can handle it all.

Our cutting edge technology, combined with a facility built for stators, allows us to handle large volumes of stators, remove the elastomer quickly, and blast the ID and OD clean (removing any trace of oil, bond, paint, rust and debris). Stators are sent back clean, degreased and ready for reline prep, saving customers time, media and money.

Reclaim Solutions Stator Service:

- Rubber Free Stators

- Degreased, Debonded

- ID & OD Blasted

- 24 Hour Turnaround

- Elastomer Inspection (NBR)

- Thru-tubing/Coiled Tubing

- Down-hole Stators

- All Stator Sizes and Lengths

- Conventional and Even Wall

- All Elastomer Types